|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

| This vise goes so far overboard with the anvil-on-the-back concept that you could almost call it an anvil with a vise on the side. |

|

|

| Rusty old vises often go for hundreds of dollars at auction. People restore them and coo about how heavy they are. |

|

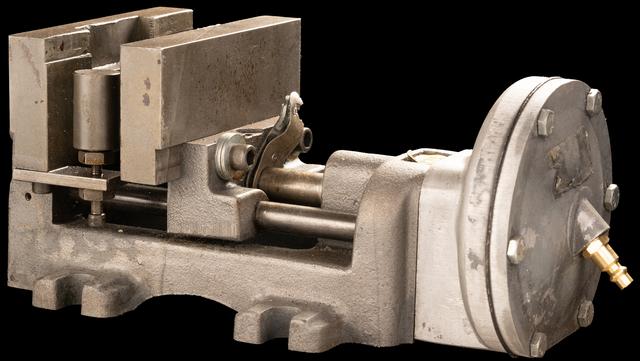

| This looks at first like a fairly normal bench vise, but it has no handle. Instead compressed air is used to push the jaws closed. This would be used for repeated clamping and unclamping in a production situation, with a foot pedal controlling the air. |

|

| I’m fond of this Swiss-made aluminum vise, mainly intended for woodworking, because I had one as a kid. (This one.) It’s lightweight, but sturdy enough, and it can be configured in many different clever ways. |

|

| This small example goes so far as to have both a flat and a horn shaped hammering area, almost like a real anvil. |

|

| This was my first vise, bought, as I remember, with money I made in High School working in a chemistry lab every Friday night because I couldn’t get a date. You could say it was my main squeeze for years. |

|

| I inherited this bench vise from the previous owner of my farm shop. It’s big. |

|

| Workbenches for proper woodworking often have built-in vises. These can be used not only to directly clamp boards, but also to hold things between bench dogs (pegs), one on the vise head and one elsewhere on the workbench surface. |

|

| This bench vise has a second set of jaws nested inside the main ones. They don’t shoot out like in the movie, but instead are used to hold pipes. |

|

| The back side of a vise really is OK to hammer on. This vise has a bit less jaw and a bit more anvil. |

|

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!