|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

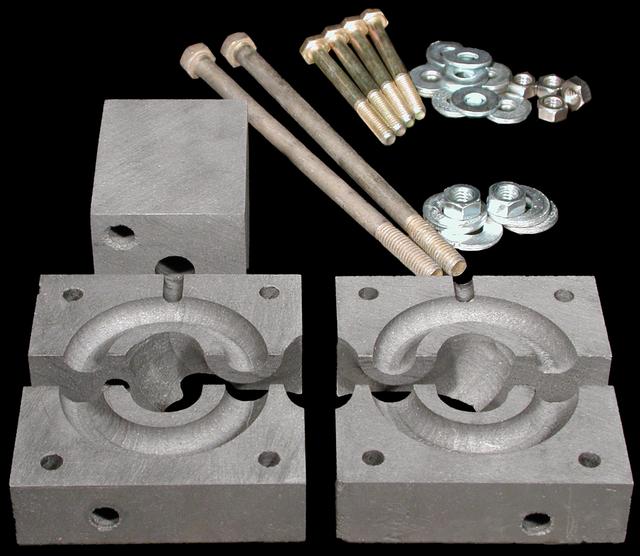

| Rod and bar molds let you cast crude bars of metal, typically silver or gold, which you can then draw into wires or roll into different shapes. |

|

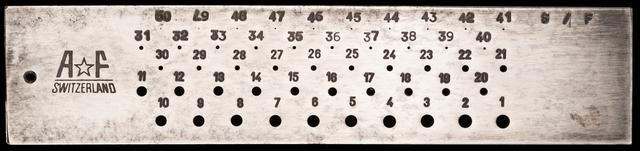

| Wire drawing plates have a series of holes that get very slightly smaller at each step. Highly ductile metals such as copper, silver, or gold can be pulled through the holes one after another, forming a thinner and thinner wire or bar each time. |

|

| I made this zinc braid in high school using old zinc roof flashing from the scrap yard. |

|

| Wire drawing plyers have wide, serrated jaws to grip the wire being pulled, and a hook to let you pull hard, or even attach a chain or rope for added pulling force. |

|

| Sulfur can be cast just like metal, but smellier. |

|

| Cast iron corn bread molds, available in kitchen supply shops, work great with zinc and tin. |

|

| I made this multi-metal chain with a complicated multi-part mold I machined out of graphite. It has links made of zinc, copper, silver, cadmium, tin, antimony, lead, bismuth, aluminum, and even iron (made by thermite casting). |

|

| Cast iron salesman’s sample stove. |

|

| My first and last attempt at making a head. |

|

| I made this replica of a zinc “crows foot” electrode for a Popular Science article about antique batteries. |

|

| Injection molding machines are usually car-sized automatic production machines. I got this little one to experiment with: it uses air pressure to force molten plastic into a mold. |

|

| My first melting cup was this cute little thing. It’s a remarkably gentle, seemingly safe way to create a pot of liquid hospital bills. The only time I had a disaster with this one was when I melted a pot of antimony, and made it a bit too hot. It caught fire as I was pouring it, which made a mess, but thankfully no hospital bills. |

|

| A small electric furnace can be used to dry molds, anneal things, or melt some kinds of metal. |

|

| Bar Ingot Mold |

|

| Graphite is an excellent material for making molds. |

|

| Mold clamp. |

|

| Melting cups like these have sophisticated PID (Proportional-Integral-Differential) controllers which automatically measure the thermal characteristics of the material being melted, then bring the temperature just up to the melting point without overshooting. This protects both the metal and the heating elements. |

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!