|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

|

| Combine pressure with heat and you have a tool that can apply hot-melt patches to clothing, or transfer images to t-shirts. |

|

| Hydraulic car crushers are big and impressive, but it doesn’t actually take that much force to crush a car. They don’t try to flatten the engine or major structural beams, they just crush the thin sheet metal skin. You can tell that this thing has a somewhat limited crushing force by the relatively small diameter of the cylinders. |

|

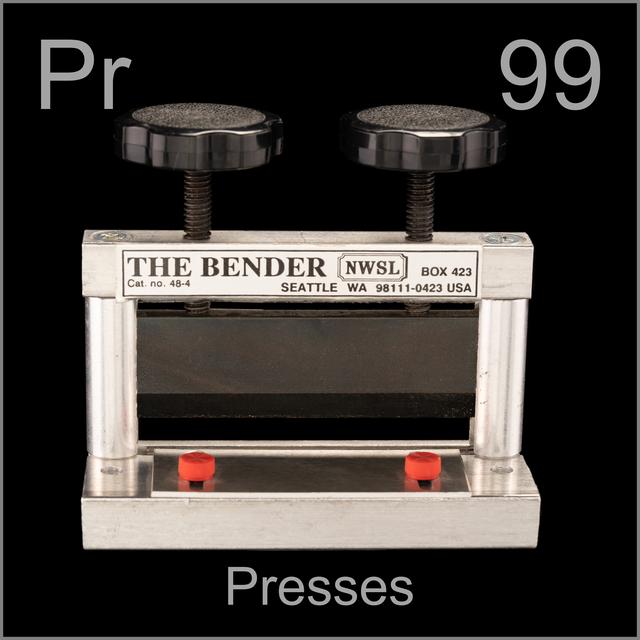

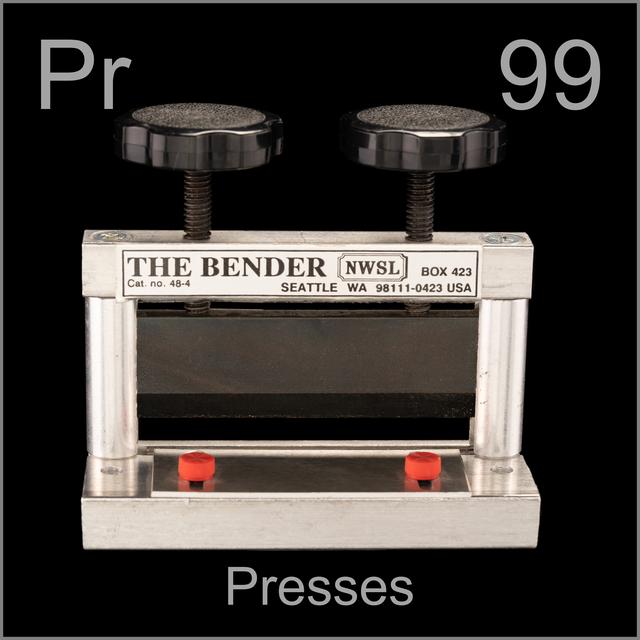

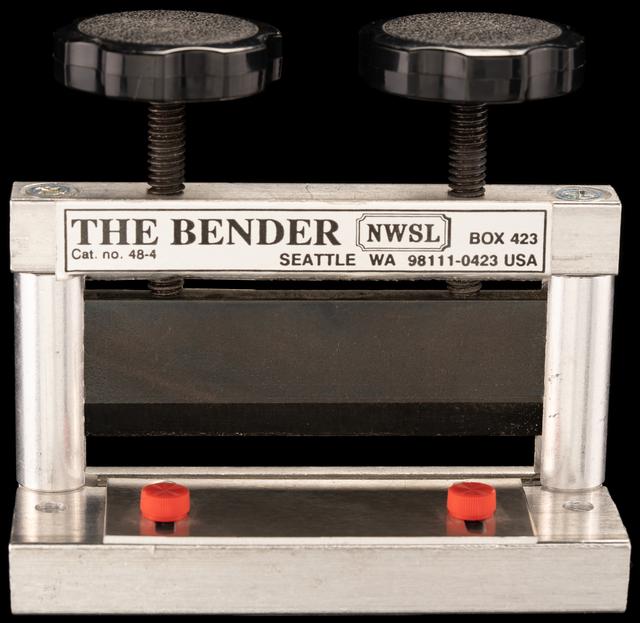

| This lovely little press brake can put a perfect bend of any angle into a piece of sheet metal up to about 2 inches (50mm) wide. |

|

| Rolling mills, like this small jewelry-making version, have two polished steel rollers which can be adjusted to a very precise separation, and then turned in opposite directions to squeeze out soft metals. This tool can turn a block of copper, gold, or silver into a paper-thin sheet or ribbon. |

|

|

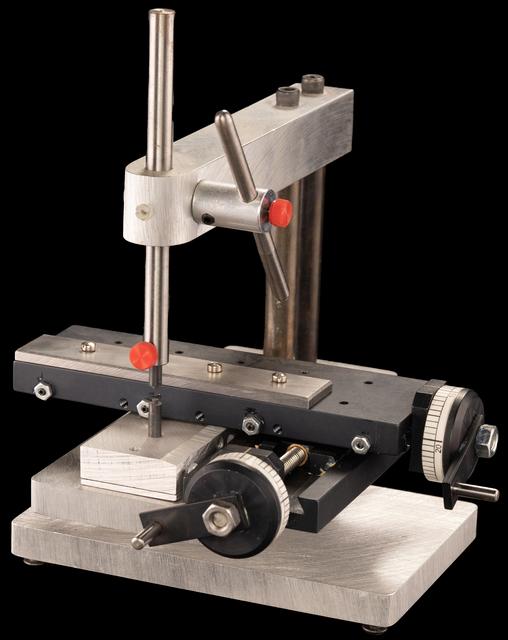

| This pin press from a model shop doesn’t press very hard, but all the force is concentrated in a tiny rod. A precision X-Y table lets you move a sheet of metal or plastic very accurately underneath the pin, so you can poke it in measured positions. |

|

| Just like the mini version above, this arbor press has a large handle that turns a small round gear against a straight gear. This is our first serious press: it can develop about one ton (2000 pounds or 900kg) of force. |

|

|

| This hoop bender uses a screw to move three rollers into position so that when a round rod is run between them, it’s bent into a hoop. By adjusting the position of the third wheel you can progressively tighten the arc until it’s just right. |

|

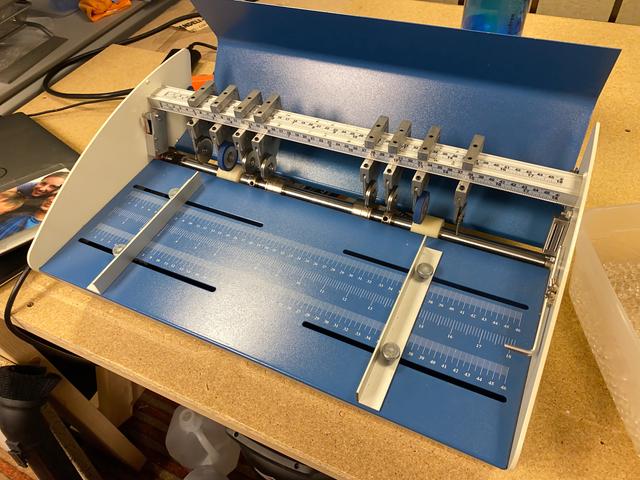

| Paper Folder |

|

| This lovely baby arbor press works just like the big ones. It came from a model-making shop, where it was probably used to precisely bend small pieces of sheet metal. |

|

| This thinner acrylic bending tools is for making sharp corners in small pieces. |

|

| This is not a hair straightening iron! It would totally destroy your hair, but does a fine job softening a section of acrylic, allowing you to twist or fold it into whatever shape you like. |

|

| These acrylic bending bars use a coil of nichrome heating wire to melt a long, straight line in a sheet of plastic, allowing you to make a clean, straight bend. |

|

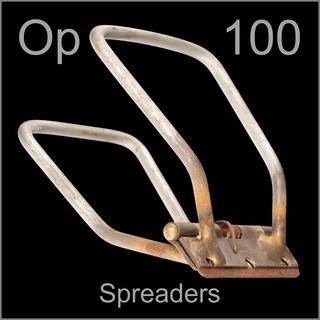

| A pipe flaring tool is what amounts to a special-purpose screw press, which pushes a cone-shaped plug into a copper pipe, flaring (spreading) the end of the pipe so it will fit in a flare fitting (a type of connector common in critical applications including brake lines in cars). |

|

| Bottle Capper |

|

| Pile Flaring Tool |

|

|

|

|

|

| Hot Press |

|

| A lot of people make their own hydraulic presses. The only manufactured parts you need are a cylinder, a pump, and some I-beams. How do you know it’s strong enough? There’s a saying: anyone can build it strong enough, it takes an engineer to make it just strong enough. In other words, make it look sturdy, when in doubt double the thickness, and it should be fine. Maybe read the specs on the shear strength of a 1-inch (25mm) Grade-8 bolt. (The answer is 41 tons, so assuming this is a 12-ton hydraulic cylinder, there is a nearly 7 times safety margin assuming the load is equally spread between the two bolts. See? No need for a fancy engineering degree for that calculation.) |

|

| Crimping bottle caps onto soda bottles is easy with this capping tool. The long handle and the fact that you can lean into it, give it considerable force. |

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!