|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

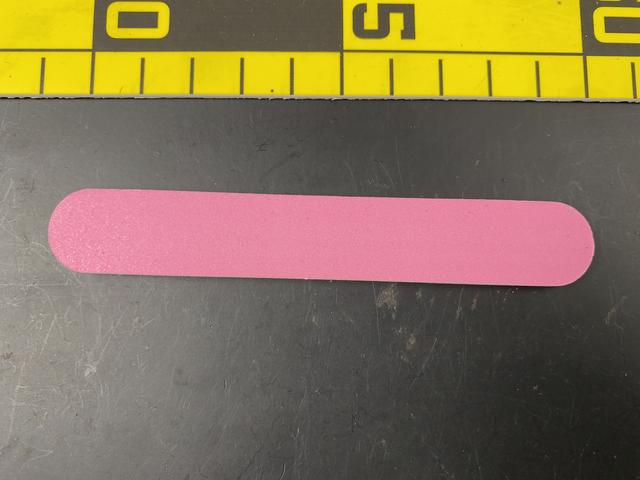

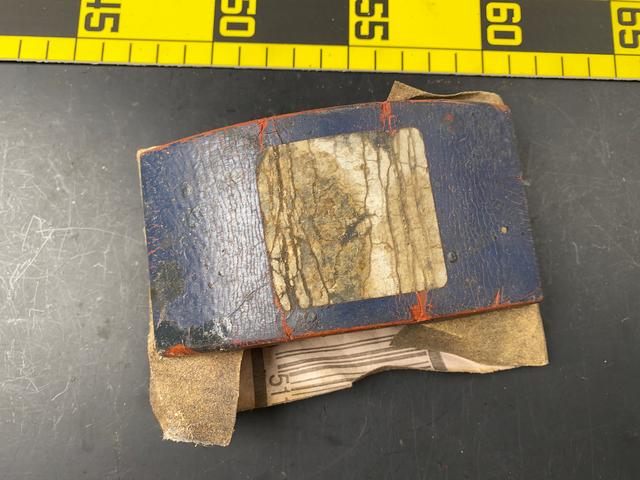

| Sanding paddles hold a dozen sheets of sandpaper you can tear off as they wear out. They are used to shape or sharped art pencils. |

|

| Linear Sander |

|

| Drum sanders are a bit like belt sanders with just one wheel. This very wide hand-held model is meant to be used on gently curved auto body panels. |

|

| These long air sanders are less likely to dig down too deep in one spot than a smaller sander. |

|

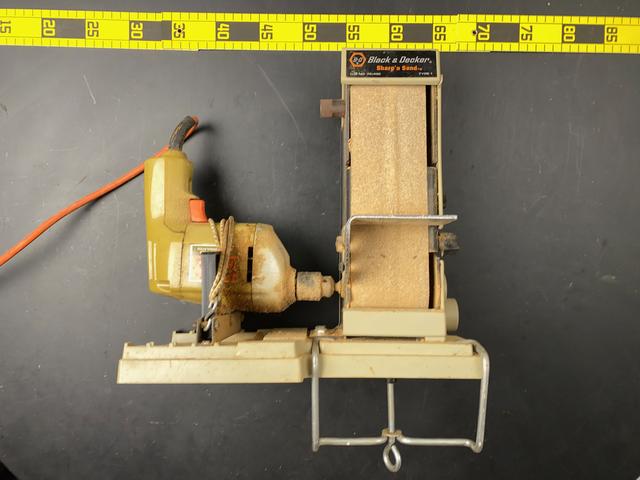

| This is my longtime belt sander. It’s gone through a lot of belts, but not many disks because I just don’t have much use for the disk side of it. |

|

| This is my pride and joy belt sander. It weighs a ton. I use it, for example, when I need to cut down the bottom of a door and can’t find my power plane. |

|

| Sander |

|

| Sander |

|

| Really narrow belt sanders, like this ½ inch (12mm) wide bandfile can reach into really small spaces. |

|

| Palm Sander |

|

| Sander |

|

| Detail sanders have pointed pads that reach into corners and between obstructions. I have not found these to be very useful on the whole. |

|

| A small electric random orbit sander has a place in every wood shop. |

|

| Tools that just spin, without the random factor, can be used as sanders, but are better suited to polishing and buffing. |

|

| Palm Sander |

|

| Narrow belt sanders can reach into tight spaces, or work on inside curves. |

|

| Pneumatic random orbit sanders are light and effective. I’ve had to resort to wearing gloves when using these tools because they get so cold from the expanding air inside. Sanding is something you tend to do for a long time once you get started. |

|

| Larger sanders are meant to be held with two hands so you can press down harder, and for a longer time without getting tired. |

|

| With the side removed you can see the mechanism, not unlike that in an army tank. Two rollers, held apart with a spring, spin the belt, and a plate in the middle applies downward pressure. |

|

| Detail Sander |

|

| I go this tool for one very specific purpose: sanding off the copper plating on one side of hundreds of pennies. I attached a tube that would hold a stack of pennies up against the belt, with a gap between the belt and tube that was slightly thinner than a penny. Each penny in turn would be pressed against the belt until it had been sanded thin enough to fit through the gap, and then it would get shot out the bottom at high speed, making room for the next penny to advance against the fence. This worked remarkably well. |

|

| A large dedicated disk sander can be used to square-off the ends of boards, or form angles by tilting the table. |

|

| Sanding Belts |

|

| Cheap plasticy belt sanders are unsatisfactory. You want something with a strong motor that can really do some damage. |

|

| Vibrating Multitool |

|

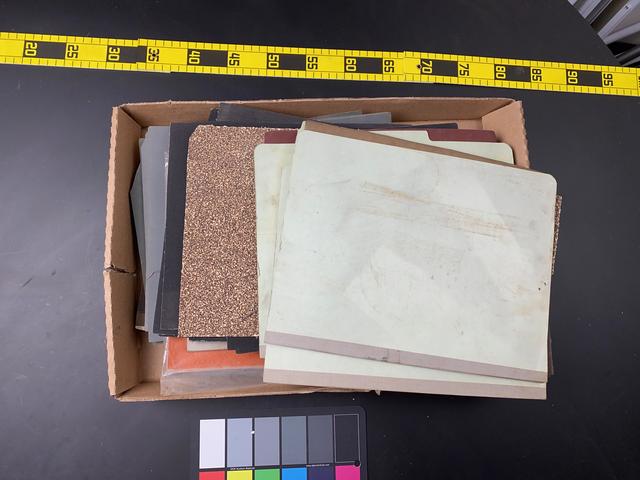

| Sandpaper comes with grit anywhere from big chunks of rock glued to paper, down to grit so fine it feels smooth to the touch. |

|

|

| Glass Nail File |

|

| I can’t help pointing out a fun fact about this antique tool: it’s a belt-driven belt sander. One belt is a rubber or leather belt connecting it to a motor or overhead common shaft. The other belt is a sandpaper belt. |

|

| Sander |

|

| Palm Sander |

|

| Sandpaper in loops is for belt sanders. |

|

| Tools like this, which attempt to leverage a drill you already have to power some entirely different tool, seem to be less common these days. Discount brands have brought the cost of dedicated tools down a lot, and these Frankentools never work well. |

|

| SmartSelect Sander |

|

| These two sanders, one electric, one pneumatic, are called “palm sanders” because they are meant to be held in the palm of your hand. |

|

|

|

|

| This vertical belt sander is pretty much the same size as my horizontal one, just rotated 90 degrees. |

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!