|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

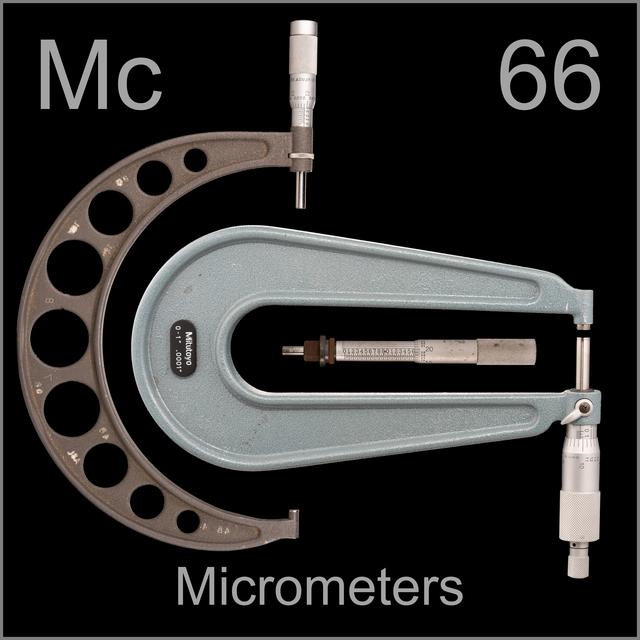

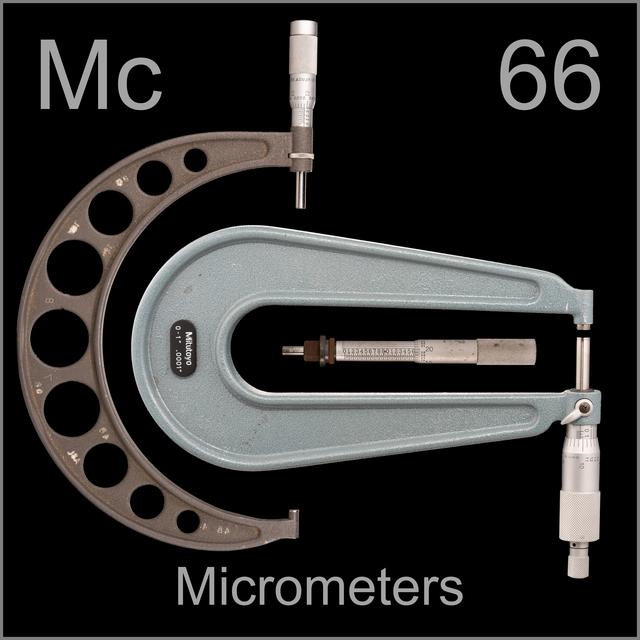

| I have never seen or heard of a micrometer with a greater than 1 inch adjustment range, but bare micrometer heads come with ranges up to 2 inches (50mm). I found this one randomly in my basement after believing for years that they don’t exist. |

|

| It’s nearly unheard of for a micrometer screw to be longer than 1 inch (25mm). So you need a separate micrometer for each 1-inch increment in measuring capacity. |

|

|

| Micrometer |

|

|

| This plastic pad is meant to insulate the C-frame from the heat of your fingers: metal expands when it gets warmer, which would introduce error. |

|

|

| Plain is nice too. |

|

| Bench-mounted micrometers can have much thicker, stiffer frames because weight is not a problem. The anvil can be adjusted to give it a wider-then-normal measuring range (the screw still only moves by 1 inch/25mm). |

|

| Thicker edges and ribs make this C-frame stiffer without being too much heavier. It’s like a miniature I-beam. |

|

|

|

|

| Deep-throat micrometers have incredibly thick C-frames to achieve the needed stiffness over such a long span. |

|

|

|

| There are a lot of different micrometer styles available. For everything else, there’s this: a bare micrometer head, ready to be mounted on whatever contraction you can come up with to solve your measuring or positioning problem. |

|

| Digital micrometers typically read to a precision of 1/20,000 inch (0.00005 inch) or 1/1000mm (0.001mm). A button lets you switch between inch and metric modes. |

|

| This is a standard 0-1” (0-25mm) Vernier scale micrometer, a very common type you will find in nearly any metalworking shop. |

|

|

|

|

|

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!