|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

| Carbide Burrs |

|

| Milling bits made of solid tungsten carbide are easy to recognize by their weight and lack of rust. |

|

| Typical milling machine bits look superficially like drill bits, but they are meant mostly for cutting sideways, not down. (Some can also cut downwards like a drill, others can’t.) |

|

| This adjustable boring tool can only be used in a milling machine (note the taper mount). It will cut a very accurate hole, but only as deep as the boring bar extends below the holder. |

|

| Some larger bits have separate, replaceable tungsten carbide inserts. |

|

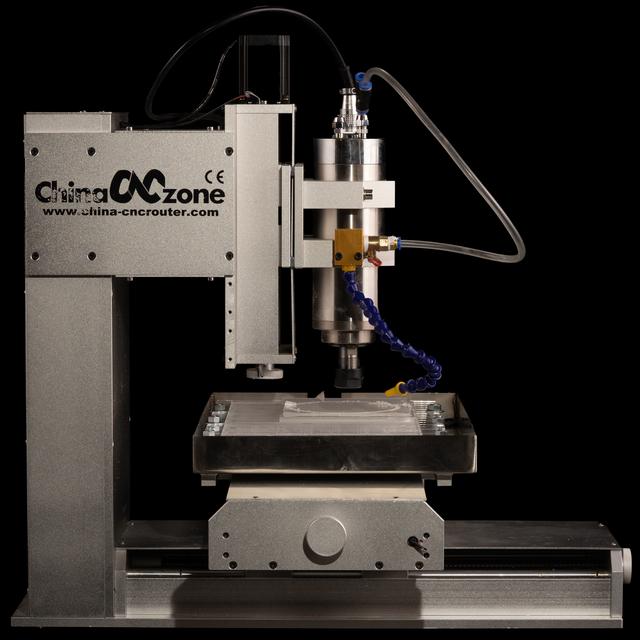

| My CNC milling machine is a small model able to work on small things. It’s mainly intended for what’s sometimes called 2.5D work, where movement in the vertical direction is limited, and for work with wood, plastic, or softer metals. What I routinely do with it is cut small brass parts for the engine kits I sell. |

|

| A full-size milling machine of the old school will weight 1-2 tons (2000-4000 pounds, or about 1000-2000kg). Lifting, or even tipping one is nearly impossible without equipment. This, however, is a miniature bench-top milling machine, which I’ve had for several decades. It has basically all the same components as a full-size version, just smaller, and of course much lighter, maybe 500 pounds (225kg). I couldn’t lift it, but I could tip it, which allowed me to slowly build up a pedestal underneath it until it was at a convenient height. |

|

| Boring bars come in assorted sizes, but are often mounted to an adjustable holder as seen on the left, to bore out holes of any diameter. |

|

| These reamers I admit I’ve never used: I got them from an auction just because they were going cheap, and who can resist a cheap reamer? Not me. |

|

|

|

| These clamps hold a vise or workpiece down to the milling machine’s movable table. |

|

| Proper clamping, with support against movement in all directions, is key to not killing yourself with a milling machine. Accessories like these let you hold things down to the table, support sections from below, and deal with awkward shapes that can’t be clamped in a vise. |

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!