|

|

Leave a comment below! Or click on an individual tool to see more or leave a comment about that tool. |

|

|

|

|

| If you want to see some really serious tinsnips, visit your local fire department. These “jaws of life” are powered by a gasoline engine running a hydraulic pump. They are used to cut through car doors to extract people trapped inside. |

|

| Benchtop tile cutters have a handle that both scribes and applies pressure to snap the tile. These things can very rapidly cut many tiles, but don’t work with all kinds. If the cuts don’t come out straight, you have to switch to using a diamond wet saw. |

|

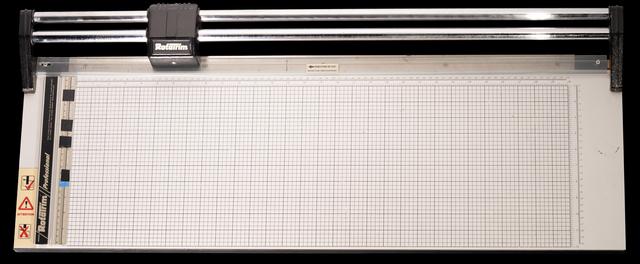

| Sliding-style paper cutters are much better for large sheets. They can be made nearly as wide as you want, because the solid steel dual linear bearing rods are held at both ends, and can easily be made very stiff. Under the rails a circular knife slices against the metal edge of the table. The blade self-sharpens against the table: I’ve used this one for decades and have never sharpened the blade. |

|

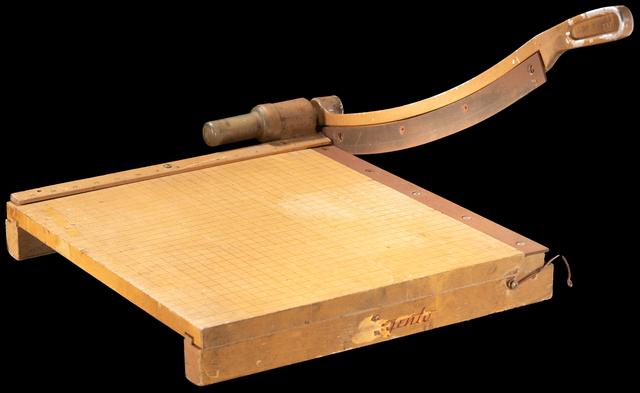

| These are called “guillotine” style paper cutters, even though this is not at all how guillotines worked. They are available up to about three feet (1m) wide, but the larger sizes don’t work too well because it’s hard to keep the blade pressed against the table. |

|

| This cute little shear was made for cutting the lead slugs created by Linotype machines to consistent lengths (note the adjustable depth stop). Lead is a very soft metal, so a simple hand tool like this was able to cut the bars, even though they were quite thick. |

|

| This home-shop-sized press brake can bend sheet metal up to 30 inches (760mm) wide, using a long handle to create a ton or more of force. This is a combination tool: the top is a set of rollers for creating gentle curves in sheet or bar stock, in the middle is the press brake for creating angles, and at the bottom is a shear for cutting sheet metal. |

|

| There are specialized shears for many specific materials. This one is for cheese. |

|

| This is a very unusual cutter. No one has been able to identify it for me, not even r/whatisthisthing. I put it here not because works like the other tools in this section, but because there’s nowhere else it fits any better. The action is as follows: you raise the handle up, which opens the wide jaws by a small amount, and slides a blade all the way back (to the right in this picture). Then you insert whatever it’s meant to cut between the jaws, and push the handle down. First the jaws close, clamping the material, and then the blade slides forward, slicing through whatever is held in the jaws. Repeat, sliding the material towards the right each time. The shape of the frame on the back (right) side indicates that you’re meant to pass a long, stiff sheet through it on either side as it’s being cut. In a fascinating twist, the iron bar that holds the blade slides in a Babbitt metal bearing, which has been cast in place inside the iron framework of the tool. That’s a technology not commonly used since the steam age. |

|

| This tobacco cutter uses gear leverage to drive its blade through many layers of tobacco leaves, to chop them up into small shreds for use in cigars. Just one of many tools used in the path from farm to lung cancer. |

|

| For tougher material, including thin sheet metal, greater leverage and a more robust blade holder is required. |

|

| These are beyond being called tinsnips, in my opinion. They combine compound leverage with huge size to cut thick metal. |

|

| This imitation Beverly Shear (generically called a throatless shear) can cut heavy sheet metal like an oversized pair of tinsnips. The “throatless” shape on the back side allows it to cut curves in either direction. |

|

| Garden Shears |

|

| Cutting vinyl tile is a bit harder than cutting paper, but the same basic style of shear still works. |

|

|

Do you have a better example of this kind of tool? Let me know by leaving a comment, and include a picture of it if you can so everyone can see!